Multiscale Process Modeling of Bulk Nanolaminates

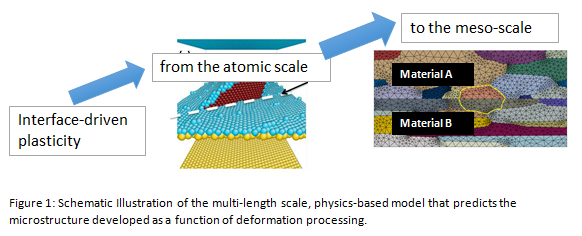

Computational models at Los Alamos National Laboratory can help guide the design of processing pathways for making stable bulk nanolaminate microstructures with tailored properties. The current model capability delivers microstructure-property relationships that evolve within the material during deformation processing. LANL also uniquely offers process-aware synthesis of bulk nanolaminates with target microstructures.

Capability Bounds

Presently, computational modeling at LANL can be applied to thermomechanical deformation within temperatures less than 0.5 Tm and strain rates less than 106/s.

Unique Aspects

LANL institutional investments have developed and validated this unique capability for materials of interest to the nuclear energy sector.

Availability

A computer cluster for parallel processing is preferred.

References

- J. R. Mayeur, I. J. Beyerlein, C. A. Bronkhorst, and H. M. Mourad, “Incorporating interface affected zones into crystal plasticity”, International Journal of Plasticity, 65 (2015) 206-225

- I. J. Beyerlein and J. R. Mayeur, “Mesoscale investigations for the evolution of interfaces in plasticity”, Current Opinion in Solid State & Materials Science, 19 (2015) 203-211

- M. Ardeljan, I. J. Beyerlein, and M. Knezevic, “A dislocation density based crystal plasticity finite element model: application to a two-phase polycrystalline HCP/BCC composites”, Journal of the Mechanics and Physics of Solids, 66 (2014) 16-31.